How Stone Carving Machines Are Revolutionizing the Art of Sculpture

For centuries, the art of stone carving has been an expression of human creativity, precision, and endurance. From ancient temples to Renaissance masterpieces, hand carving with chisels, hammers, and other tools was the foundation of sculpture and architectural detail. Today, the rise of advanced stone carving machines, coupled with digital technologies, has transformed the industry, merging tradition with innovation to achieve results that were once unimaginable.

From Hand Carving to CNC Stone Carving

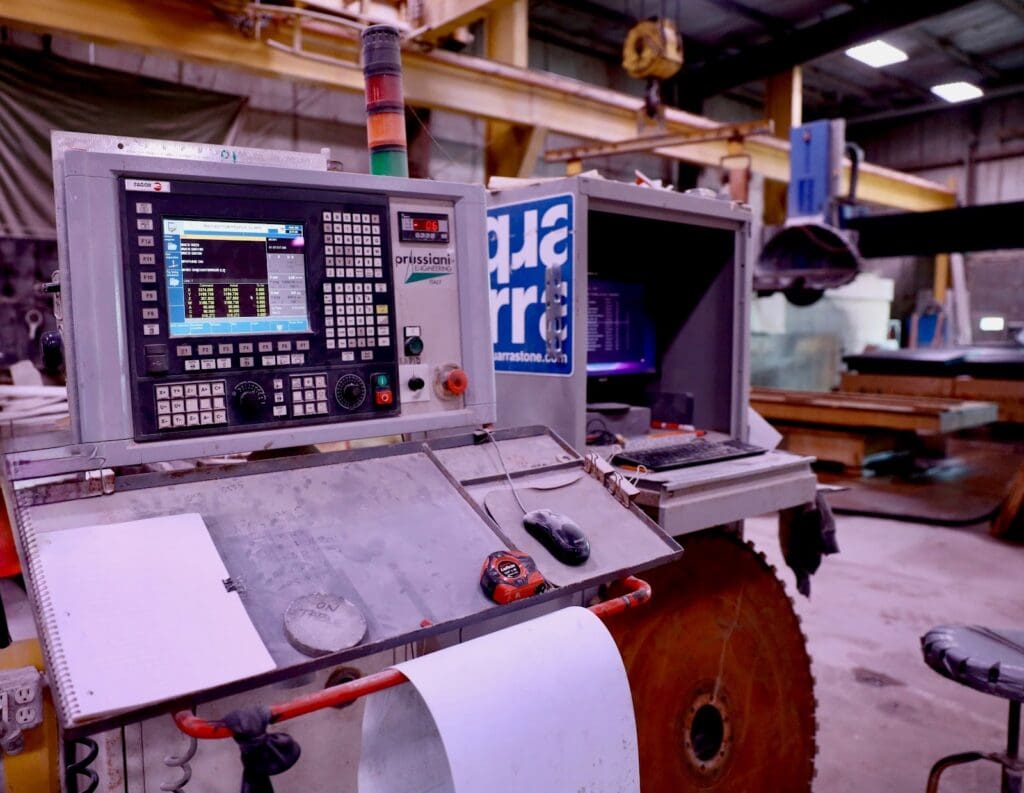

Traditional hand carving will always hold a place of respect in the history of carving stone, but modern CNC stone carving offers unmatched accuracy and efficiency. A CNC machine uses digital files and multi-axis milling to cut and shape stone blocks into complex forms with incredible detail. Whether the goal is a monumental sculpture, architectural ornament, or decorative relief carving, the precision of CNC stone technology ensures consistency while reducing production time.

The Process of Cutting Stone with Technology

At the heart of modern stone carving machines is advanced stone cutting and milling technology. Using a high-speed spindle, operators optimize cutting speed and depth to maximize material utilization while achieving smooth finishes on marble, granite, soapstone, slate, limestone, and even engineered options like artificial stone and artificial marble.

This adaptability allows artisans and architects to create everything from custom sculptures to decorative display panels, architectural building scopes, and even specialized company plates. In fact, the same technology used for cutting stone can be adapted for producing ceramic tile, embossed mould designs, fair signs, or even a chocolate mould—showcasing the versatility of modern fabrication.

Expanding Possibilities in Art and Design

With digital designs guiding each machine setup, artists can achieve levels of precision previously unattainable by hand alone. The ability to mill across multiple axis means that highly intricate surfaces, textures, and shapes can be realized with ease. This innovation supports not only large-scale construction and architectural projects but also specialized art installations, cabinet details, window surrounds, and unique door carvings. At Quarra Stone, we see stone carving machines as a bridge between tradition and contemporary design.

Why Stone Carving Machines Matter for Modern Projects

The benefits of stone cutting technology extend far beyond efficiency:

- Precision and Detail – Fine engraving, intricate milling, and flawless surfaces are possible with advanced stone carving machines.

- Versatility of Materials – From marble and granite to quartz, jade, soapstone, metal, glass, wood, and even aluminum, these machines are suitable for diverse materials.

- Efficiency and Cost Savings – Optimized cutting stone methods reduce waste and improve material utilization, delivering stronger results at better value.

- Scalability – Whether creating monumental sculptures, public art installations, or detailed building models, machines can scale to meet the demands of modern construction.

The Essential Role of Artistry

While machines bring speed, accuracy, and consistency, the human touch remains essential. Artists and artisans refine the final surface, ensuring each piece carries not just technical perfection but also artistic soul. This harmonious blend of tradition and technology ensures that every project stands as both functional and artistic.

The Future of Stone Carving

As technology continues to advance, the capabilities of stone carving machines will only grow—allowing us to achieve new heights of creativity and craftsmanship. From blue stone memorials to soapstone carvings, from quartz countertops to slate wall art, the possibilities are limitless.

At Quarra Stone, we are committed to exploring these advancements while honoring the traditions of stonework. By merging modern CNC stone carving with timeless craftsmanship, we deliver projects that balance durability, precision, and enduring beauty.

Partner with Quarra Stone

Looking to bring your vision to life with stone carving machines and expert craftsmanship? Whether you need sculpture, architectural elements, or custom design, Quarra Stone’s artists and fabrication experts are ready to help you realize your project.

FAQs About Stone Carving Machines

1. What is the difference between traditional stone carving and CNC stone carving?

Traditional carving relies on chisels, hammers, and hand tools, making it time-intensive but deeply artisanal. CNC (computer numerical control) stone carving uses digital design files and multi-axis milling machines to cut, shape, and engrave stone with high precision and speed, opening possibilities that are difficult or impossible by hand alone.

2. What types of materials can CNC stone carving machines work with?

Modern stone carving machines are highly versatile. They can handle marble, granite, quartzite, soapstone, slate, and limestone, as well as engineered options like artificial marble. Many machines are also capable of milling non-stone materials such as wood, glass, and even certain metals.

3. What advantages do stone carving machines offer for modern projects?

CNC machines provide precision, efficiency, and scalability. They reduce waste, shorten production timelines, and allow for intricate engraving or sculptural detail at both small and monumental scales. For architects and designers, this means better cost control and greater creative flexibility.

4. Do stone carving machines replace the role of human artisans?

No. While machines bring accuracy and speed, the artistry of stone carving still relies on human expertise. Skilled artisans refine finishes, enhance textures, and ensure the final product reflects both technical perfection and artistic vision. The best results come from blending machine precision with handcraft.

5. What types of projects benefit most from CNC stone carving?

CNC technology is ideal for large-scale architectural projects, public art installations, memorials, detailed ornamentation, countertops, wall panels, and sculptures. It’s especially valuable when projects require complex geometry, repeated elements, or ultra-precise detail at scale.